Aluminum vs. Copper Coldplate CPU Cooler Benchmark – Does Metal Matter?

Posted on

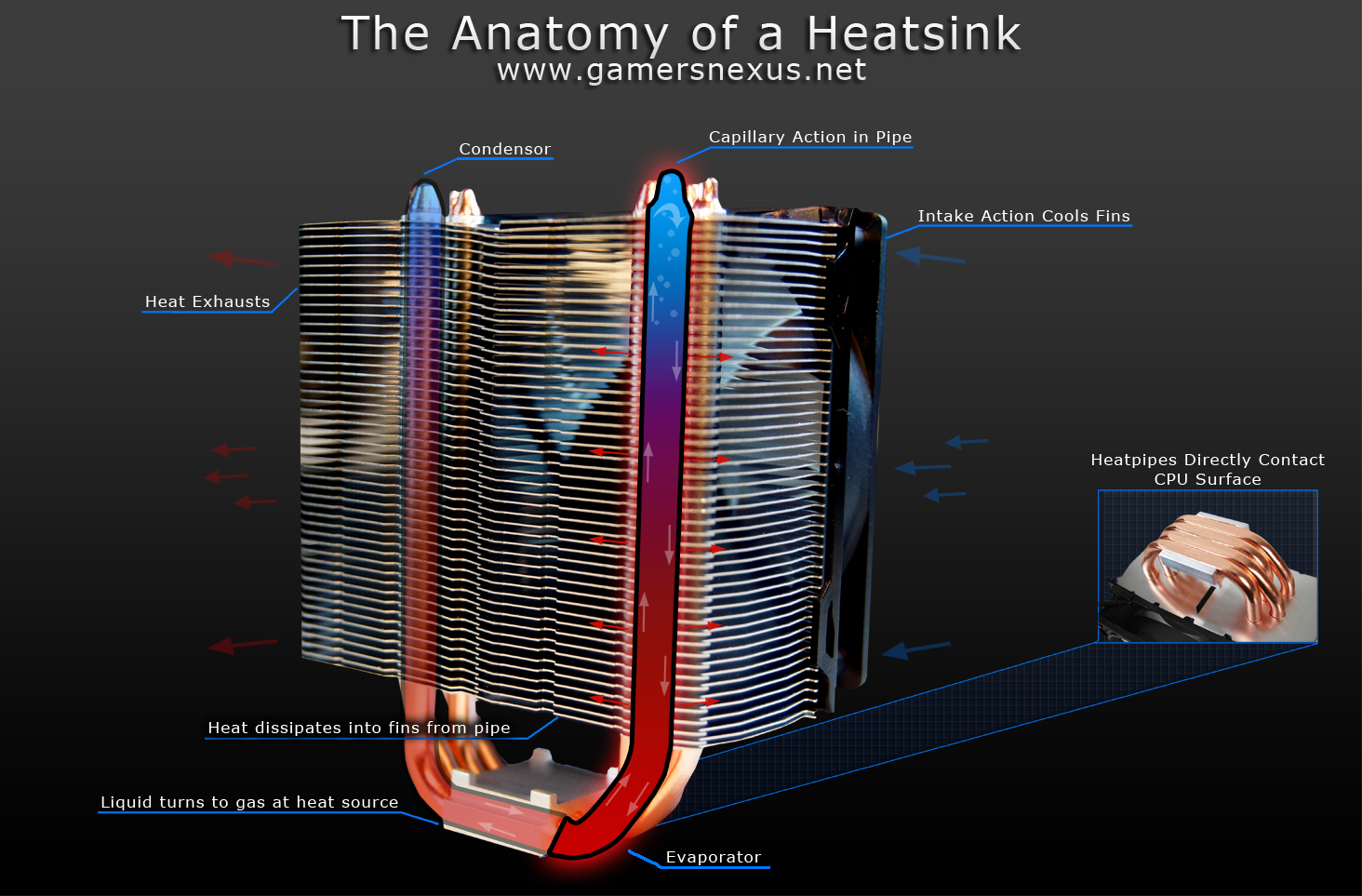

It's been a number of years since we posted an in-depth look at CPU coolers. Our 2012 CPU Cooler Anatomy post explained the basics of air cooler design, highlighting the use of capillary action within copper heatpipes to conduct heat from a copper coldplate. Liquid coolers function more similarly to a car's radiator system and yield significantly more efficient thermal performance, but also call some common practices into question – like the efficacy of copper versus aluminum.

The basics indicate that copper does, by any and all scientific measure, thoroughly trounce aluminum when it comes to thermal dissipation potential: Copper cools at about 400 Watts per meter Kelvin at 25C (401W/mK) and aluminum is around half that, sitting at 205W/mK at 25C. That's nearly a 2x difference; for perspective, most stock thermal compound is in the 4-5.6W/mK range, with air (no thermal compound) at ~0.024W/mK.

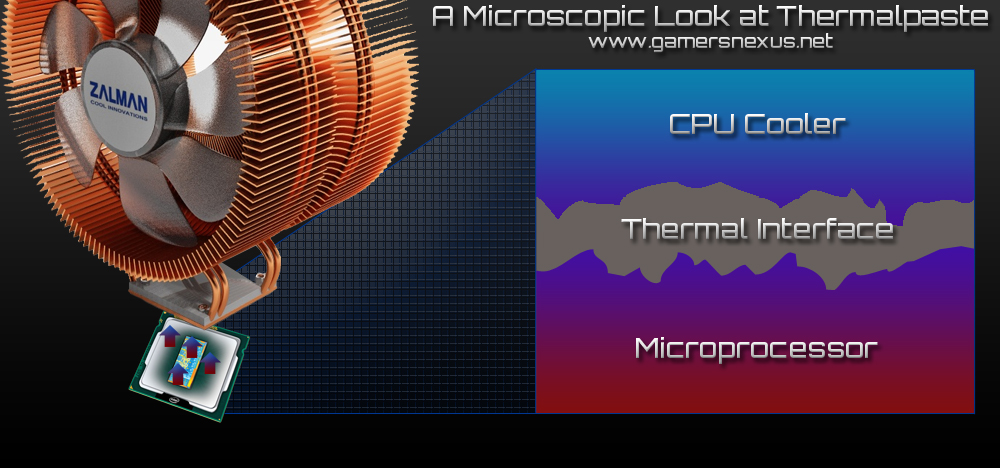

Thermalpaste (TIM) is used as an interface between the coldplate and the CPU's integrated heat-spreader (IHS), where it fills microscopic imperfections in the surface of the IHS to facilitate improved heat transfer to the CPU cooler's coldplate. We illustrated this previously in a graphic:

This thermalpaste fills the imperfections; without it, air would remain trapped between the IHS and coldplate, where it would ultimately increase temperature of the CPU. Liquid coolers are identical in this aspect – a cold plate is mounted to the IHS, heat is conducted through TIM and into the coldplate, and then the cooler whisks the heat away. The difference emerges in the details: Liquid coolers use microfins on the unseen side of the coldplate, where water is propelled through channeling and circulated to a radiator, where standard radiator design takes over.

Today, our test is to determine whether copper is still necessary in a coldplate when using highly efficient cooling solutions. Liquid coolers are a good benchmark for this – first off, it's hard to find both an alloy and copper model of an otherwise identical cooler, but they also offer such great cooling efficiency that materials come under question.

Benchmarking two similar liquid coolers against one another, this article looks at copper vs. aluminum CPU cooler coldplates for thermal performance. We used an Asetek 550LC and 510LC, two units described below, to conduct all tests found herein.

Reviewing The Coolers: Asetek 550LC & 510LC Specs

For this test, we used two Asetek CLCs that are as similar as realistically feasible for testing. Asetek is a CLC supplier that provides manufacturers with a cooling solution. NZXT and Corsair are two of the best-known manufacturers who retail Asetek-made CLCs, like the Kraken X61 and Corsair H100i GTX.

The 510LC and 550LC Asetek coolers used here are 120mm options, measured at 120x120x27. Both units utilize Asetek's newest fifth generation of cooling design, which includes some changes to improve pump efficiency and mitigate noise by lowering pump speed; because of overall efficiency improvements, the lowered pump speed has minimal impact to actual cooling performance.

For frame of reference, Corsair's H100i GTX uses this new “Gen 5” cooling architecture, as do the H80i GTX and H110 GTX. NZXT's most recent X61 and X41 coolers are built with an effective Gen 4 of Asetek cooling technology, but differentiate themselves somewhat notably from other Gen 4 coolers by offering variable pump speed. To our knowledge, the pump speed baseline of the – we'll call it “Gen 4.5” – NZXT coolers is approximately 3600RPM, but can be lowered by the user; the Gen 5 baseline pump speed is ~2800RPM, more or less, and offers a significant noise reduction.

Corsair also makes use of these “Gen 4.5” coolers in its H75 ($65 - $75), which uses Asetek's 550LC cooler in 4.5 form. The 550LC is used in the H50 ($50 to $60) and H55, with the only major difference between the two being inclusion of both Intel and AMD retention brackets for the H55.

Note that although the manufacturers do use supply from Asetek, all have input on design and can institute changes in the final product. Manufacturers will sometimes use differently-sized radiators, better fans, and longer or shorter tubes to make a more unique product offering.

The 510LC isn't really available right now, but could be ordered by a manufacturer for branding and design tweaks. It is almost an assurance that the 510LC would have some sort of cost reduction due to the use of aluminum over copper, but the unit is otherwise effectively identical to the 550LC. Where the 510LC is seen heavily, though, is in system integrator (SI) PC builds; the CyberPowers and iBuyPowers of the world utilize the 510LC as a CLC that is often cheaper than air cooler “upgrades.”

Test Methodology

For this test, we used a similar test platform to our GPU tests, but with a few modifications. To assist in building a separate, designated cooler and power testing rig, Enermax has provided a massive 1500W EMR1500EWT PSU for our test bench. This will be heavily utilized in impending multi-GPU thermal benchmarks. Other than this PSU change, the other components were the same as our GPU bench shown below:

| GN Test Bench 2015 | Name | Courtesy Of | Cost |

| Video Card | NVIDIA | $650 | |

| CPU | Intel i7-4790K CPU | CyberPower | $340 |

| Memory | 32GB 2133MHz HyperX Savage RAM | Kingston Tech. | $300 |

| Motherboard | Gigabyte Z97X Gaming G1 | GamersNexus | $285 |

| Power Supply | Enermax EMR1500EWT | Enermax | $226 |

| SSD | HyperX Predator PCI-e SSD | Kingston Tech. | TBD |

| Case | Top Deck Tech Station | GamersNexus | $250 |

| CPU Cooler | This is what we're testing! | Asetek | - |

Testing was conducted using an i7-4790K in both stock and overclocked configurations. The stock configuration has the CPU an 88W TDP, easily within the cooling range of the 550LC and 510LC. Our overclock test saw a clock bump to 4.5GHz from the 4.0GHz base. Note that all power controls and C-states are disabled for thermal tests, ensuring a more replicable test environment.

The CLCs were connected using their pre-installed thermal compound and were not tampered with pre-install.

Once installed, ambient was logged with a thermistor and the CPU was left to idle at desktop for two minutes. During this two-minute period, thermals are logged using AIDA64 and stored in a CSV file for analysis. At this point, a twenty-minute burn-in test is initiated using Prime95 with LFFTs on the CPU. We find that equilibrium is reached around the 10-15 minute mark, depending on the bench and cooler (and if an open air bench or a case is used).

All results are logged to a file and then analyzed and calculated in a spread sheet. Results are presented as Delta T over ambient (21C), so we're calculating-out ambient from the results to produce a delta value.

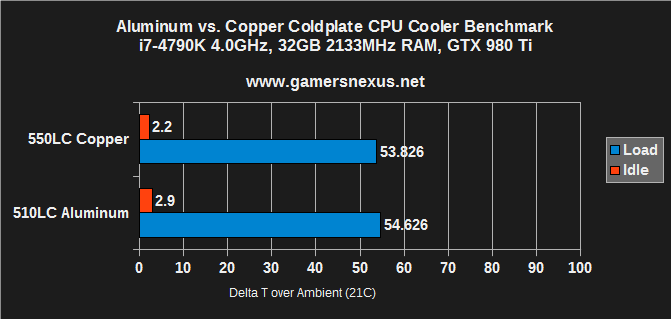

Benchmark: Copper vs. Aluminum CPU Coolers

The OC and stock performance results are below:

Stock testing reveals a measurable (but mostly insignificant) difference of ~0.8C under load and 0.7C idle. The 0.8C delta will show no performance advantage toward the copper-cooled CPU. Overclocking provokes a 1.1C delta between the two when under load.

Conclusion - Asetek 510LC vs. 550LC

The 0.8C delta is mostly insignificant, especially if there's a noteworthy cost savings on an aluminum coldplate unit – that'd go far in budget systems.

There are a few items we should note, though: Despite the relatively small difference, a real-world scenario where you're presented with identical copper and aluminum coolers is fairly unlikely. Except in this specific instance – were manufacturers to begin producing the 510LC – most coolers will use copper coldplates, whether you want it or not. Additionally, this was strictly limited to CLC testing and is not inclusive of air coolers, which may exhibit different results given the more metal-intensive approach to dissipating heat through fins. It might be worth revisiting this topic using some old Zalman all-copper coolers, though.

Given two highly efficient units with only copper vs. aluminum coldplate differences, going alloy could save a few bucks. This is the case when buying from SIs, some of which offer both the 510LC and 550LC at varying prices. For system builders, it's just not an issue that'll come up very often when purchasing CPU cooling components.

Still a cool test, though. Copper doesn't have nearly the impact I'd expect it to given the massive W/mK advantage, but that's also a testament to efficient pump and radiator design.

- Steve “Lelldorianx” Burke.