Computex 2018 saw the unveil of pro overclocker Der8auer’s phase-change cooling solution, called the Phase-Shift Cooler, using a similar solution to 3M Novec. Novec coolant has been demonstrated before (and was again at Computex) for its low boiling point and ability to cool a system using “only” a condenser and coolant, but is on the restricted substances list in the EU for containing PFCs. This eliminates 3M Novec from the list of products available for consumer retail, and forced Der8auer and Caseking to find another solution. The pair did find another liquid with a low boiling point, but did not share with GamersNexus the specs of the liquid. Regardless, it’s the same idea.

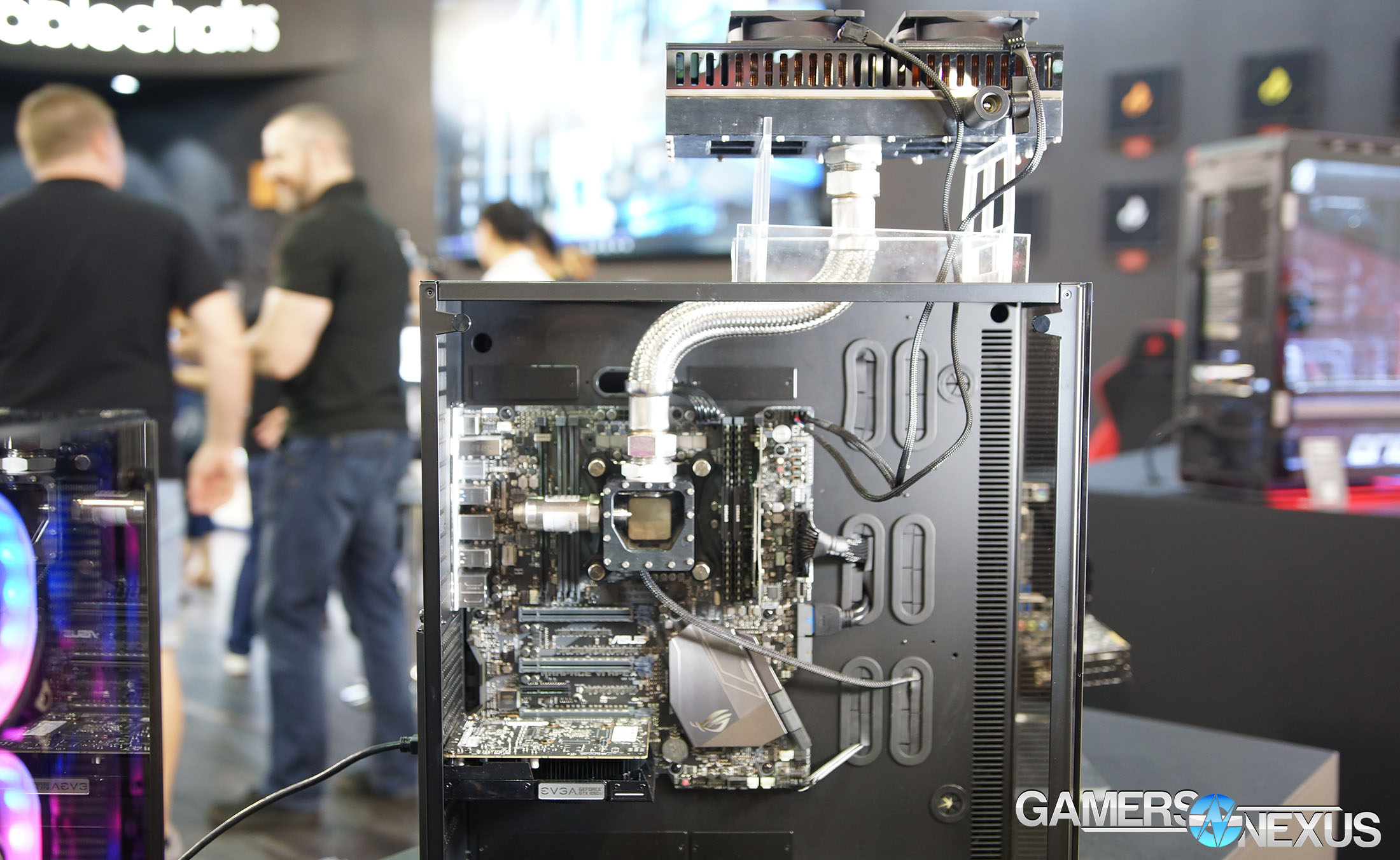

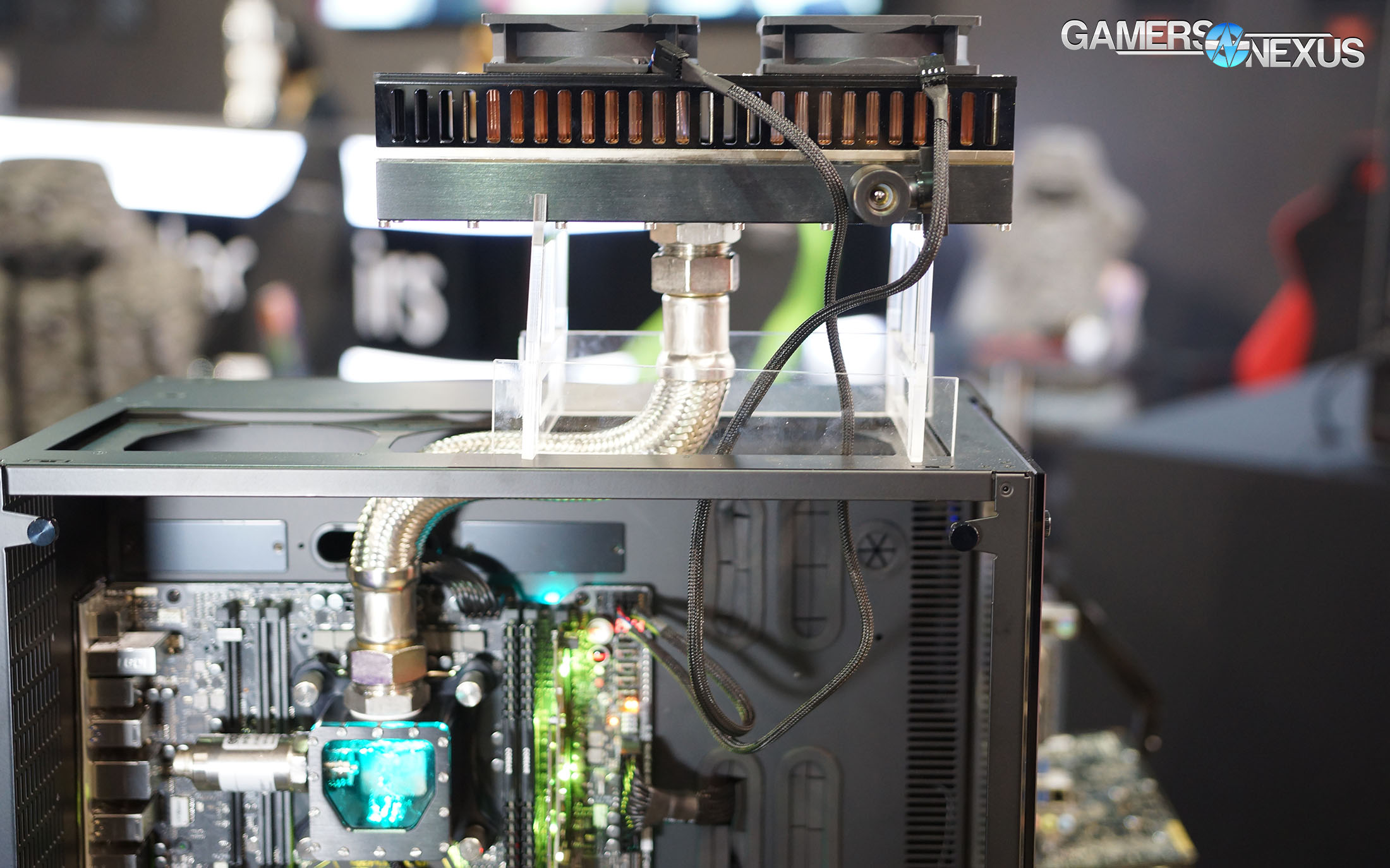

For Der8auer’s Phase-Shift Cooler, about 40ml of liquid sits in a CPU block, attached via (presently) a large hose to a condenser and tank. Atop a 7920X with Prime95 running, roughly creating about a 140W heat load, the coolant evaporates and drafts up the pipe as a gas. As the gas hits the tank, it encounters the condensers and gets cooled by a pair of copper heatsinks and 90mm fans. Once condensation forms, it slowly drips back down the tube and returns to the block.

All of these parts are functionally prototypes right now, but Der8auer anticipates shrinking tube size down to a 14mm hydraulic, black hose shortly, and also hopes to reduce the total size of the tank+condenser combination to ~60mm or shorter. The 90mm fans will be replaced with 120mm fans, but high-end fans aren’t necessary – the liquid and phase-change process removes most of the heat from the socket, the fans are just there to help with the condensation process.

Also of limited tenure, a pressure sensor is on the model shown at the booth and juts across two DIMM slots, but will be removed later. It is a debugging feature, at present. A valve is also on the tank and is used for controlling pressure, but will be removed later. Pressure and boiling point are directly correlated with this coolant – as one goes up, the other goes up.

Der8auer hopes to sell this as an actual product at some point, and notes competitive performance with other 240mm CLCs, but with removal of the pump. Removing the pump eliminates pump whine, obviously, and also eliminates pump failure. This reduces RMA concerns to mostly fans, and those almost never fail.

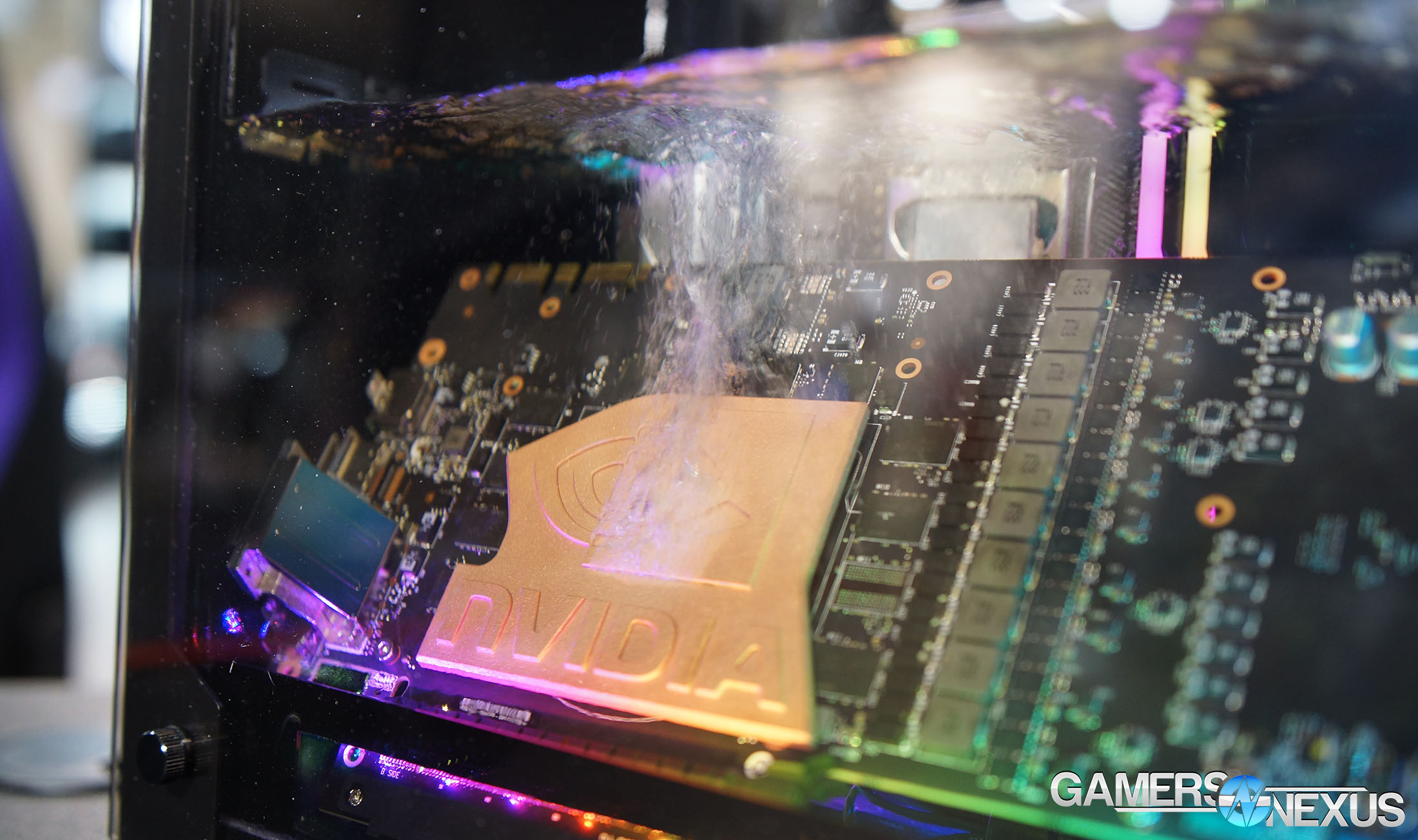

Caseking and Der8auer also had a Novec exhibition system on display, using a completely sealed and pressurized tank with 3M Novec 7100 coolant. This particular model of coolant has a boiling point of 61C, whereas Novec 7000 has a boiling point of 34C. As a result, it isn’t the best for performance (although does fine), but is easier to use for a show system. Cost is a major factor. The system uses a copper block atop the GPU, which is intentionally roughed-up for increased surface area and cooling potential. The block is about 4mm, aiding in heatsinking capabilities. As liquid boils, it enters the top chamber, hits a condenser, and returns as liquid. An EK loop is used to cool the condenser actively.

Learn more in the video above.

Editorial: Steve Burke

Video: Andrew Coleman + Keegan Gallick