Early reports surrounding Vega GPU packaging indicated minimally two different package processes, though later revealed a potential third. For the two primary forms of Vega GPU packaging, we’re looking at clear, obvious differences in assembly: The silicon (GPU + HBM) is either encased in an epoxy resin (“molded”) or is not encased at all (“resinless”). There is another type of resinless package that has been shown online, but we haven’t yet encountered this third type.

The initial concern indicated that packaging process could impact HBM2 contact to cooler coldplates – something for which, after working on this content, we later discovered new data – and we wanted to test that mounting pressure. Just last night, days after we finalized this content piece, we found another data point that deserves a separate article, so be sure to check back for the follow-up to this piece.

In the meantime, we’re using a chemically reactive contact paper to test various Vega GPUs and vapor chambers or coolers, then swapping coolers between those various GPUs to try and understand if and when differences emerge. Some brief thermal testing also helps us validate whether those differences, which would theoretically be spurred-on by packaging variance, are actually relevant to thermal performance. Today, we’re testing to see the mounting pressure and thermal impact from AMD’s various Vega 56 & 64 GPU packages, with a brief resurrection of the Frontier Edition.

Note: We used torque drivers for the assembly, so that process was controlled for.

Just for an explanation of what we’re doing, AMD’s Vega GPUs ship in at least two types of packaging, if not three. One of them uses an epoxy resin that raises to fully encompass the GPU and HBM, flattening the height and protecting the interposer. We found this mounting method on three of our Vega 64 reference cards, two branded by Gigabyte and on loan from a generous reader, and one from AMD as a press sample. The second method is resinless assembly, which leaves the interposer less protected and sort of recessed from the GPU and HBM. This also means a more topographical contact area. We found this resinless method on our Vega 64 Strix card from ASUS and on our Vega 56 reference card, from the initial press batch. Our Vega: Frontier Edition card used the epoxy resin method – the first one – as did the three Vega 64 reference cards.

In speaking with board partners, it seems the resinless versus epoxy packages are not chosen by the partners, and that it’s basically dependent on when the batch of chips went out. Thus far, there is no hard data to suggest that either package type is superior to the other. They originate from different factories, and so are inconsistent in assembly – but that’s not necessarily bad. We’ll be testing that here.

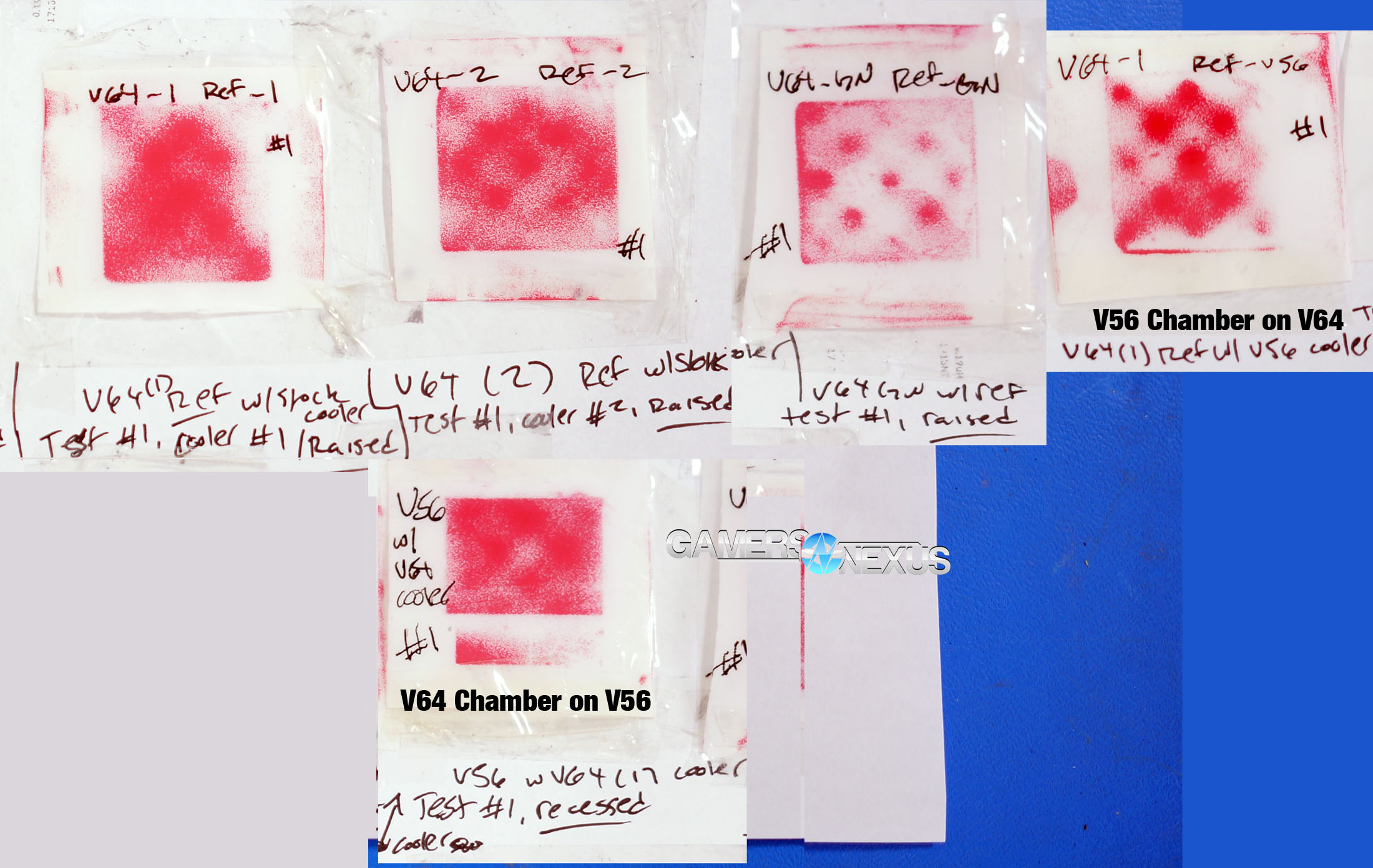

Our first order of business is to determine the mounting pressure and contact area from the various heatsinks. For this testing, we are using chemically reactive paper that turns red when pressure is applied to the paper. We are running at least two application passes per GPU, with a total of six tested devices. Some of these tests will include swapping coolers between GPUs, which will help determine if limited mounting contact is more a result of the vapor chamber cooler or of the package assembly. Most of these tests are done without thermal paste, so you’ll need to remember that thermal compound exists to fill imperfections in surfaces.

Remember that we can only test for this sample size, and also remember that, regardless of what you see here, there’s no consistency to Vega 64 vs. Vega 56 mounting pressure or coolers. It is largely random.

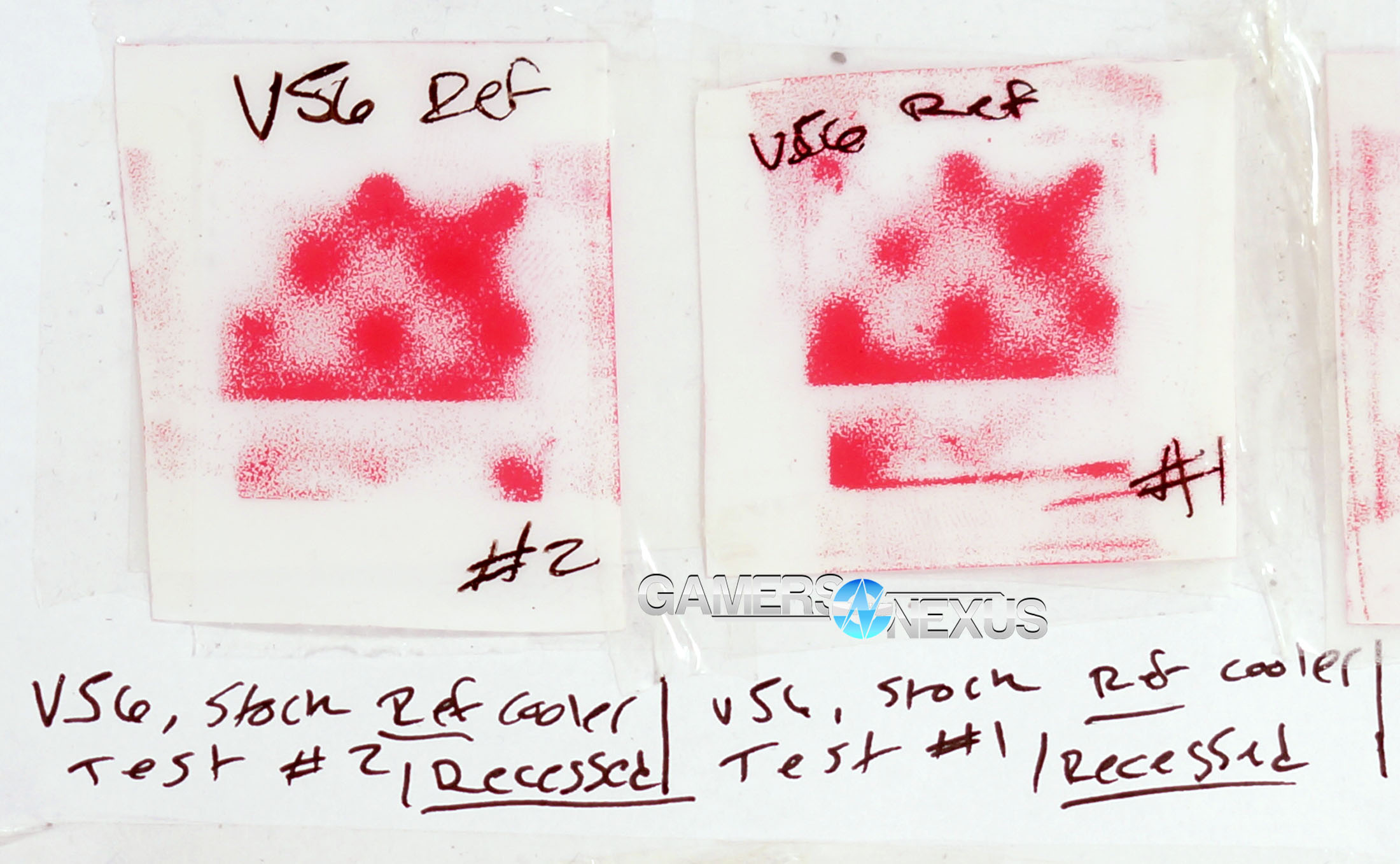

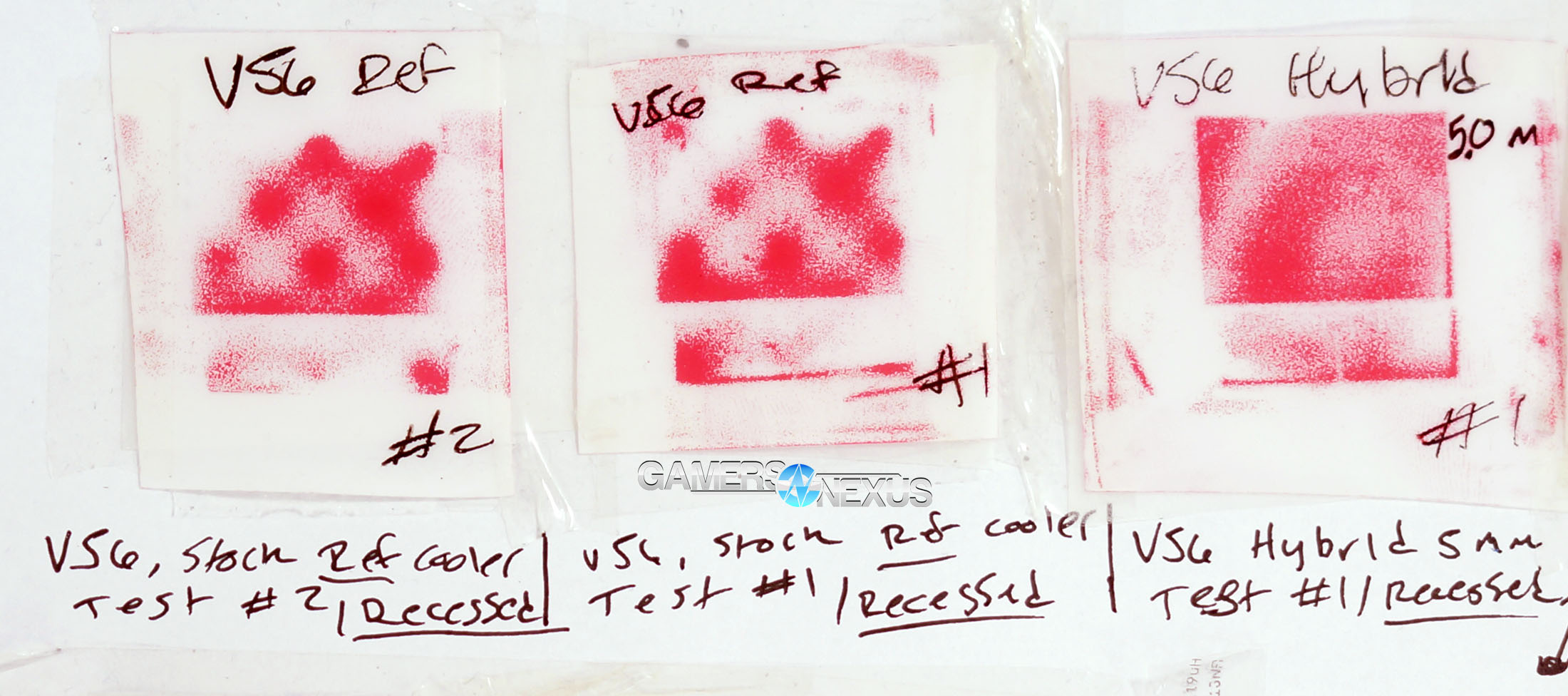

Vega 56 Reference GPU Contact Pressure Tests

We’ll start with our Vega 56 GPU, as that provides the most varied results to quickly understand how this all works.

With its stock, reference cooler that came on the sample, our Vega 56 GPU shows minimal contact to the vapor chamber for the HBM2, with spotty contact for the GPU. We can highlight where the HBM would be illustrated, if it had fuller contact.

The GPU itself has some contact to the chamber, but cylindrical shapes appear in each of the first two tests. This isn’t a mistake: There are actually cylindrical columns within vapor chambers, preventing the chamabers from collapsing on themselves. This is normal for all vapor chambers. The fact that we see them means that there’s greater contact pressure in the areas of those columns. If there’s enough interest in the comments, we may dissect one of these coolers in a few days.

This contact patch overall is theoretically sub-optimal, but remember that thermal compound exists exactly for this purpose. Hypothetically, the vapor chamber cooler should outweigh the negatives of limited contact area, and TIM will fill those gaps; HBM also has low heat flux, so it can better get away with less contact than the GPU could.

Vega 56 vs. Hybrid Contact Comparison

Here’s a look at our Hybrid mod, from way back when Vega 56 first got here. We first thought our Hybrid mod would have worse contact than the vapor chamber, but repeat testing proved better contact with the Asetek CLC plate on the Floe 360. This is because it’s flat to slightly convex, and so we see greater contact with the HBM. Remember, this GPU is one with the recessed packaging, lacking any epoxy resin around the borders. The GPU coverage is also significantly better than the Vega 56 reference cooler, if we superimpose them.

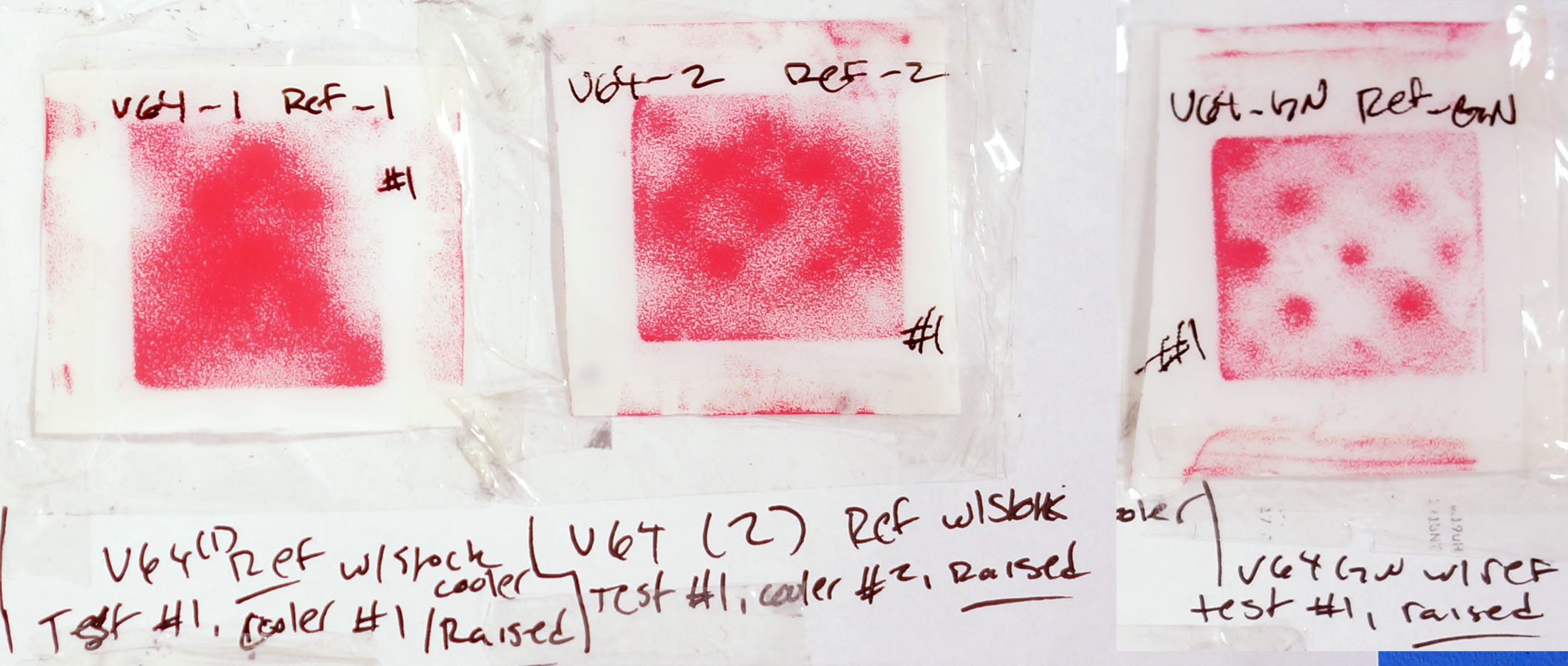

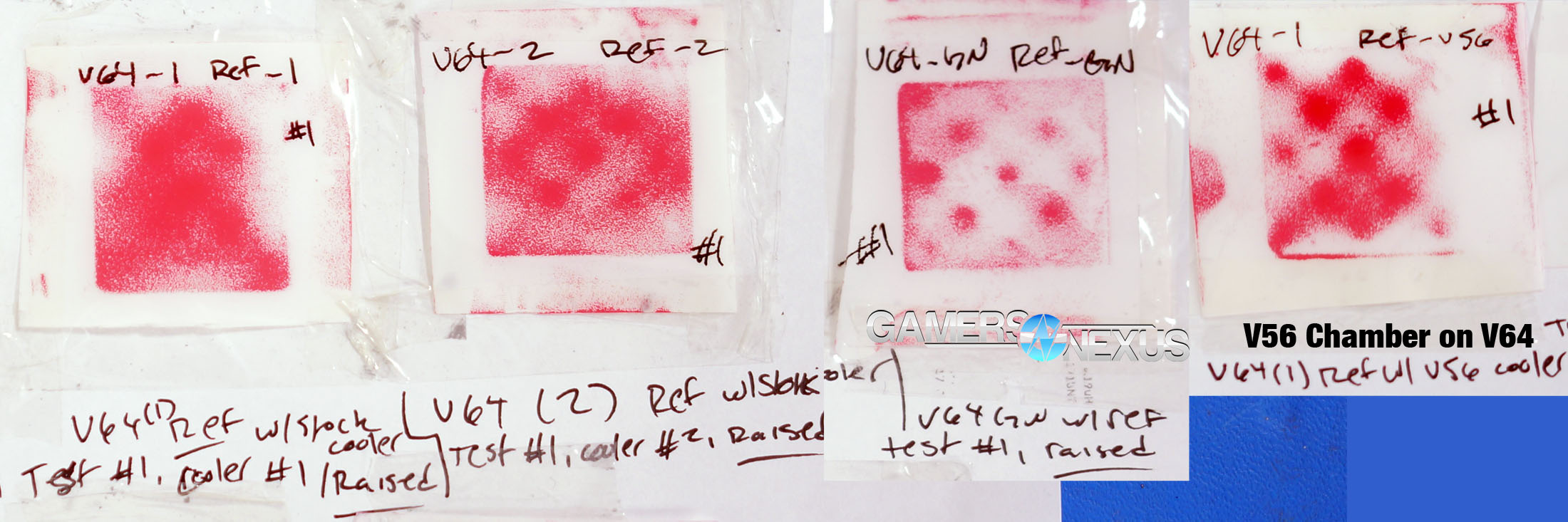

Vega 64 Reference Contact Pressure

The next GPUs are our three Vega 64 reference cards, two of which were purchased by a reader. All three units use the epoxy resin packaging, and so the footprint appears wider than that of the silicon packages. This is because our contact paper is reacting to pincing pressure applied by both the raised epoxy and by the silicon, with the other side pressured by the vapor chamber. The two Gigabyte-branded reference cards have significantly better HBM coverage than our previous Vega 56 test, and have overall better GPU coverage. You’ll notice, however, that the earlier sample Vega 64 reference card has poor contact when compared to the two Gigabyte units, which come from the same batch.

Vega 64 with Vega 56 Chamber Comparison

To test this, we planted our Vega 56 vapor chamber atop the best Vega 64 test, labeled as V64-1, and found the following: much worse coverage, despite being tested on the exact same package. This indicates a levelness issue with the Vega 56 vapor chamber, which also carries over to our Vega 64 press sample card.

Vega 56 with Vega 64 Chamber Comparison

For further testing, we took the best Vega 64 cooler, that’d again be V64-1, and stuck it to the Vega 56 card. We now see significantly better coverage, rivaling that of our Hybrid mod. The coverage is much better on the GPU, but still lacks for the GPU. We think this may have something to do with lower HBM2 package height, as initially reported by Tom’s Hardware, but we are not yet fully positive.

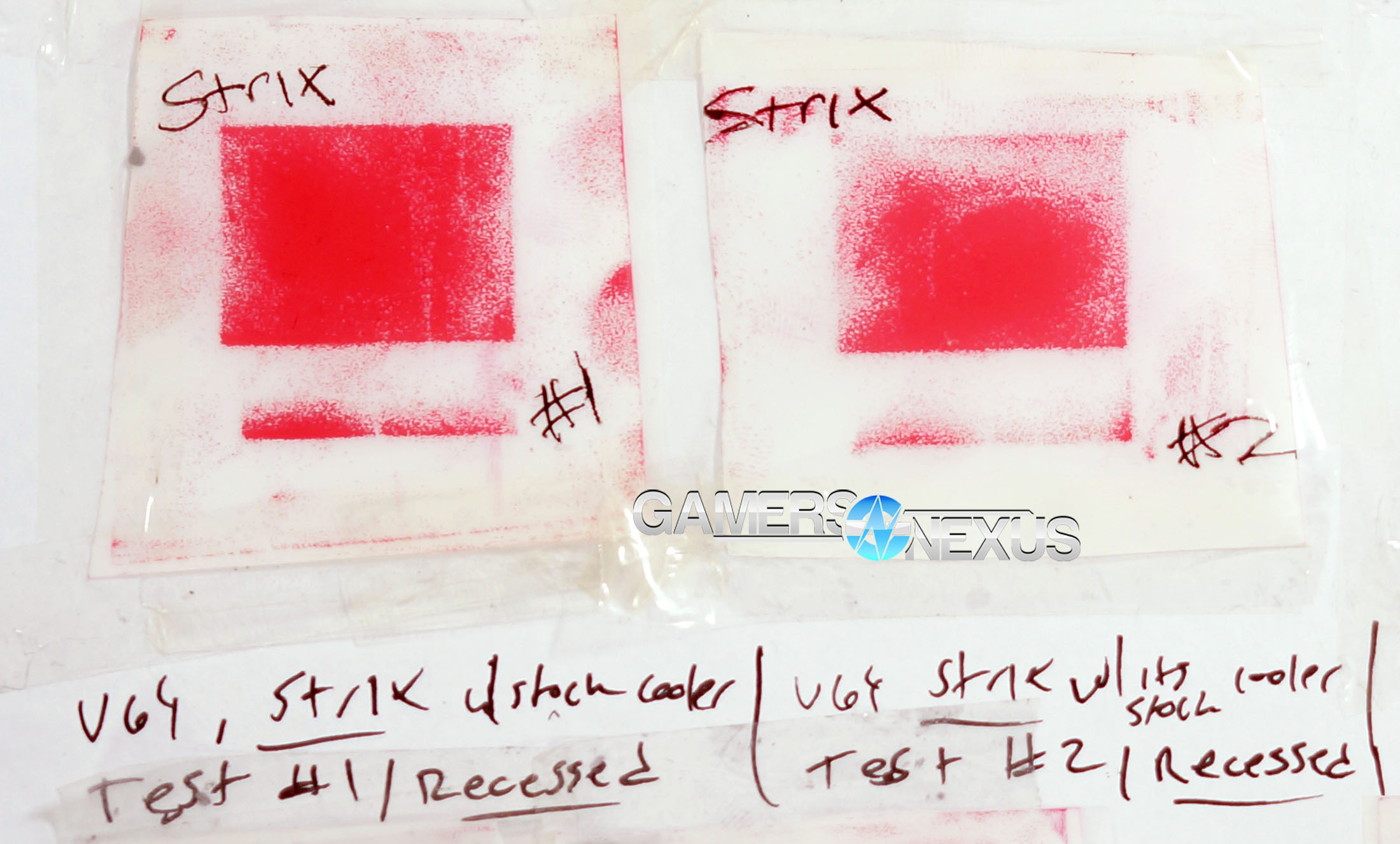

ASUS Vega 64 Strix Contact Pressure Comparison

The next test is our Vega 64 Strix model from ASUS. In this one, we see the best GPU coverage we’ve yet spotted, with still lacking HBM coverage. The Strix coldplate is nearly perfectly flat, as it is smoothed and nickel-plated, without the supporting rods of a vapor chamber. We think that this correlates with the recessed package design, as our Strix model V64 card lacks the epoxy resin. Of course, this is a sample size of just a few cards, so we have to implore that correlation does not equal causation – but it is a potential finding.

What is notable, though, is that the cylindrical divots do not appear with the flat coldplate of the Strix card, which is attributable to its cooler design. That does not inherently mean a superior cooler, as vapor chambers make up for it in other ways, but is another potential point of data for when the Strix undergoes review testing.

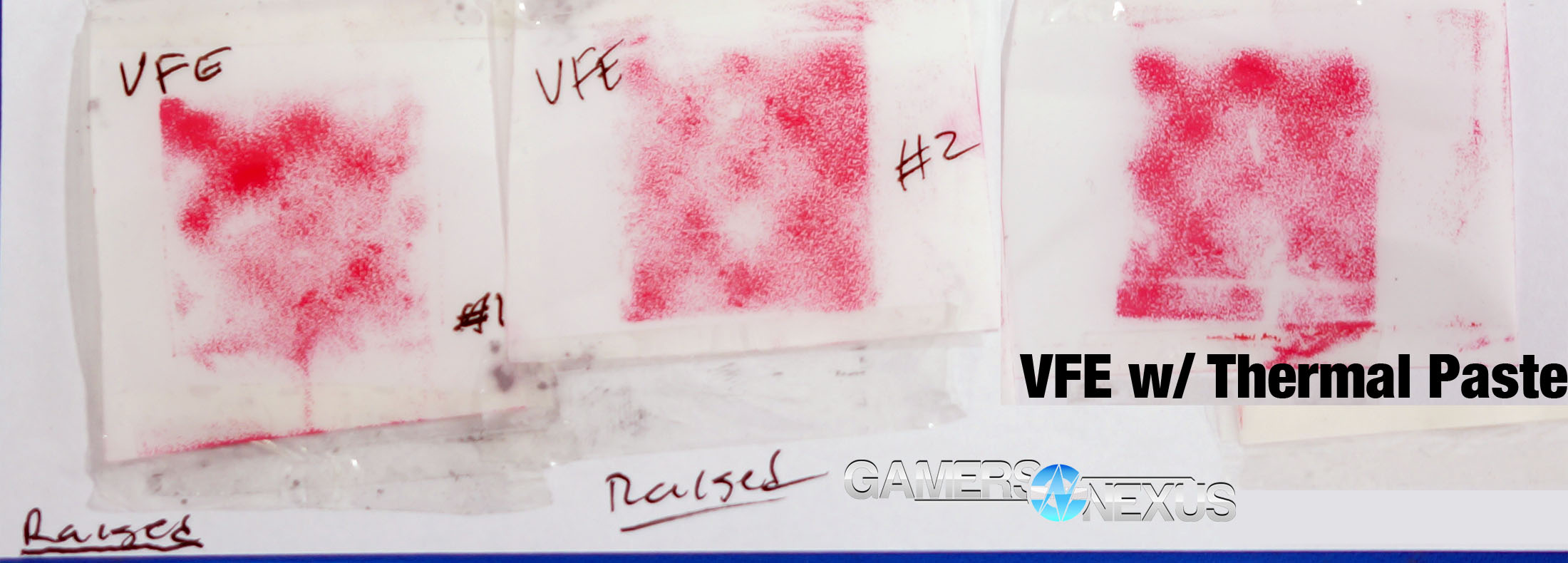

Vega: Frontier Edition Contact Pressure

The final test was conducted on our Vega: Frontier Edition card, which we purchased in the very first round of Vega products. This GPU uses an epoxy resin package, just like the three Vega 64 reference cards; unfortunately, it also has similarly poor contact to our early press sample Vega 64 card. Again, correlation does not equal causation, but a point worth exploring would be whether the later models – like the Gigabyte Vega 64 units – underwent improved quality control for cooler contact pressure. We can’t be certain without more units. If you’d like to send us some on loan for testing, tweet @GamersNexus to get in touch.

For now, we can only note that our VFE card had more limited contact. We tried applying thermal compound underneath our contact paper, just to see if coverage area improved. Coverage was improved a bit, but we don’t think this test is particularly conducive to working with the pressure paper, so we’ll discard that data for now.

Let’s pull the most important results, then look at their thermal behavior:

Quick Test: Thermal Behavior from Vega Contact Pressure

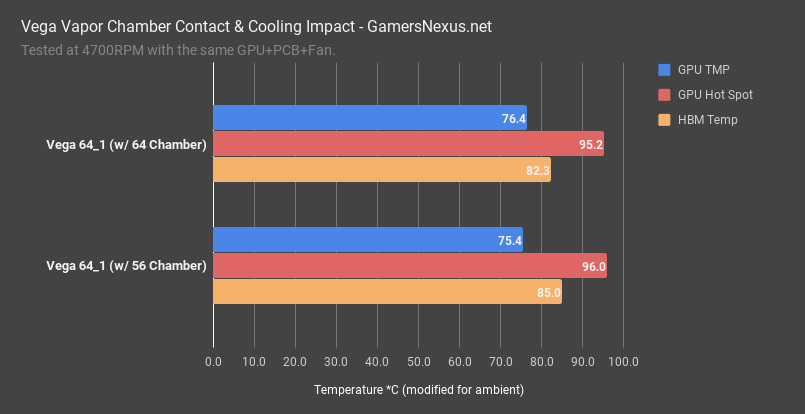

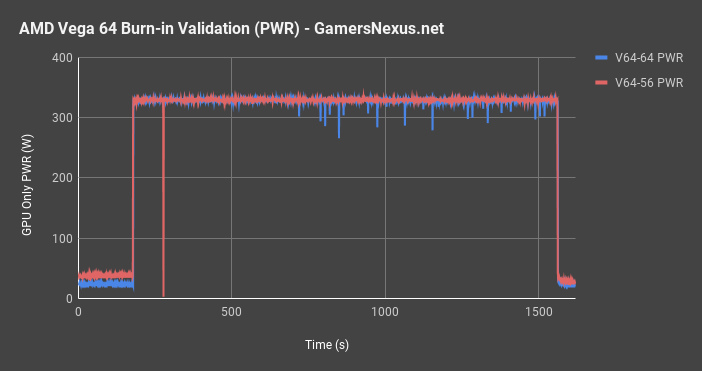

This is the best coverage Vega 64 vapor chamber versus the worst coverage chamber from our Vega 56 card. We have kept the fan, baseplate, and faceplate, and have swapped only the vapor chambers. The GPU is also the same. We have controlled for ambient and applied a delta modifier where necessary. We ran this test multiple times.

With power virus burn-in and blower fan speeds at 4700RPM, the Vega 64 vapor chamber, which had fuller coverage, keeps us at 76.4 degrees on the GPU, 95.2 degrees for the reported GPU hot spot, and 82.3 degrees for the HBM temperature.

Swapping the Vega 56 chamber onto the card, we end up with a GPU temperature that is about 1-degree lower (and more or less within variance), along with hot spot temperature that is 0.7 degrees higher. The hot spot temperature is fully within test resolution, so can be declared as functionally the same as the Vega 64 chamber. The HBM temperature, however, is a full 3 degrees higher with the Vega 56 chamber, which is outside of variance and is repeatable.

Fortunately, an extra 3 degrees won’t hurt anyone. There’s quality control variance, but we’re not running significantly hotter than the cooler already operates.

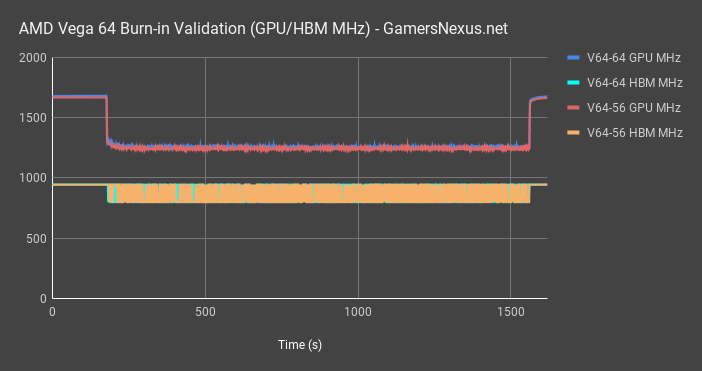

(Above: This is a power virus load, so the frequencies are lower than typical workloads -- but the point is to generate heat, which this does)

(Some spikes on the blue line, but not enough to impact the data we average)

Just for parity, here’s a frequency chart to demonstrate that the tests operated at the same frequencies. We can also show GPU-only power, which plots the cards as consuming equal amounts for each test.

Conclusion

There’s not a huge difference, at the end of the day, but there is a quality control variation present. Patterns drawn from this initial sample size would indicate more potential for vapor chamber quality differences than anything else – but we have more coming soon, now that we just got more cards in. The contact issues seen above are resolved largely by thermal paste, and the vapor chamber’s benefits more than make-up for its contact pressure variations, which are normal for a vapor chamber (those cylindrical shapes would happen with every vapor chamber, as the cylinders are used internally to prevent the chamber from being crushed). Just make sure there’s thermal paste in there -- nothing different from any other GPU, really. Thermally, we have not yet seen a major difference in packaging performance, but we also haven’t yet shown any packages with the earlier reported 40um lower HBM2. Again, more on that very soon, but it’ll take time to process the next round.

So far, from these cards tested, there’s not a lot to be worried about. The initial reports from Tom's and Videocardz got a lot of interest, but were never looked into beyond that. Thus far, from a small sample size, there is variation. Sure, there are some seeming quality control concerns (that also correlate with our earlier samples, so it may be resolved on later runs), but nothing that’ll break the cards or even perform appreciably worse.

One note: Be very careful if cleaning resinless packages. It is easy to scrape the interposer with a fingernail or other tool and cause irreversible damage. The epoxy resin packages should be fine and are protected.

Editorial: Steve Burke

Video: Andrew Coleman