As with any modernized adaptation of an existing technology, closed-loop liquid coolers (CLCs) have become almost fad-like in their adoption. In part, this is because CLCs actually do have very legitimate advantages over traditional air coolers - they are highly noise-to-temperature efficient, for one thing, and have an aesthetic appeal for some users. The other part of this liquid cooling craze, though, I believe is attributable to a general doting of something new.

The thing is, not every liquid cooler is going to be inherently better than similarly-priced air coolers. Just having liquid in tubes (rather than copper-encased capillaries) does not make the units predisposed to superior cooling qualities; this said, a well-constructed liquid-cooling solution can certainly trounce a well-constructed air cooling solution -- it just comes down to the engineering in each product and consideration of other differences (noise). There's a reason we use radiators for large, hot things (cars, for one) in tandem with traditional air-cooling engineering (also found in car cooling systems in the form of air intakes, copper/aluminum sinks, etc.): Both have their place for optimizing maximized potential for thermal dissipation.

CLCs have been the center of a burgeoning demand for quiet and effective CPU thermal dissipation lately, but they're still fully-capable of spinning fans just as fast and producing just as much noise as a 4000RPM air cooler. In terms of making your "air vs. liquid" decisions, it's really going to come down to appearance and temperature-vs-noise benchmarks; we've previously explored how air coolers are built, and from that research, it's quite clear that air units aren't going away anytime soon.

This CPU liquid cooler round-up aims to benchmark and review the Corsair H90 & H110 and NZXT's Kraken X40 & X60 CLCs (140mm and 280mm radiators, respectively).

We'll outline the specs for each unit before delving into the basics of how liquid coolers function (being that this is our first review of CLCs), the objective performance data, and other notes.

Corsair H90, H110; NZXT X40, X60 Specs Comparison

| Specs | Corsair H110 | NZXT X60 | Corsair H90 | NZXT X40 |

| Radiator Size | 280mm | 280mm | 140mm | 140mm |

| Fan Count | 2x140mm | 2x140mm | 1x140mm | 1x140mm |

| Fan Spec | 1500RPM +/- 10% ~35dBA 4-pin PWM 94CFM | 800-2000RPM +/- 10% 4.5V-12V 21-37dBA 4-pin PWM 54-98.3CFM | 1500RPM +/- 10% | 800-2000RPM +/- 10% 4.5V-12V 21-37dBA 4-pin PWM 54-98.3CFM |

| Extras | 2 Year Warranty | 2 Year Warranty LED-Backlit Nameplate Control Software | 2 Year Warranty | 2 Year Warranty LED-Backlit Nameplate Control Software |

| Compatibility | LGA1155, LGA1156 LGA1366, LGA2011 AM2, AM2+, AM3 AM3+, FM1, FM2 | LGA1155, LGA1156 | LGA1155, LGA1156 | LGA1155, LGA1156 |

| Price | $130 | $140 | $90 | $100 |

NZXT X40 & X60 vs. Corsair H90 & H110 Video Review

How Closed Liquid Cooling Loops & Radiators Work: CLC Engineering

Because these are some of the first liquid units we're reviewing, I'll give a bit of a top-level overview of how radiators work and what makes them so space-efficient. If you already know how a cooling radiator works in a car or AC applications, well, you already know how it works in a computer.

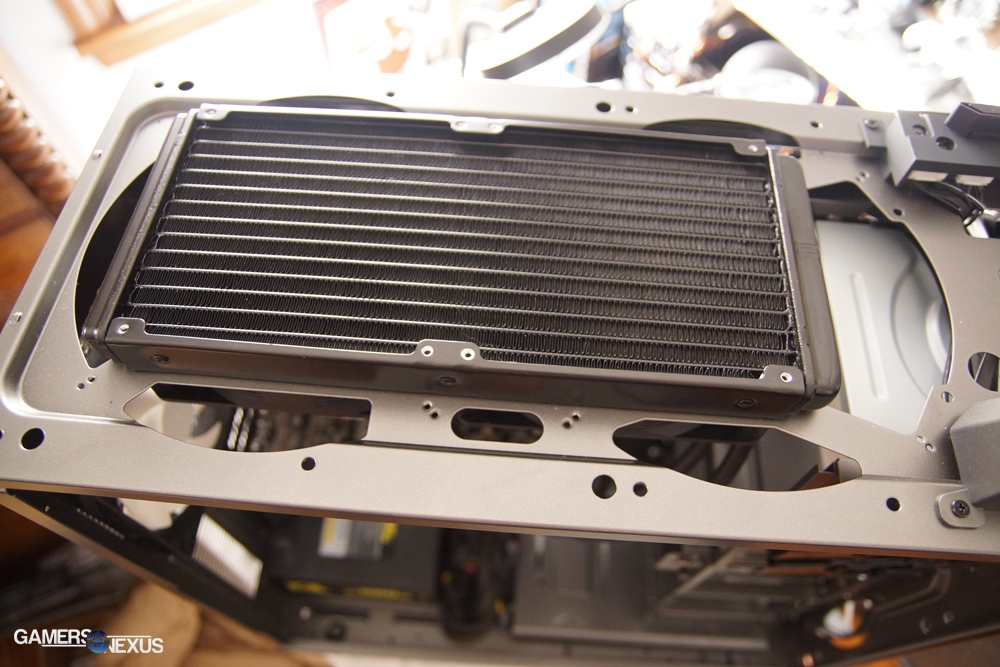

It's the same concept, really: The radiator is a composition of an outlying metal frame, hosing, lots of aluminum fins, and a couple of fans. At the most basic level, a computer's closed-loop liquid cooling system (or any CLC, really) works as follows:

Let's start at the source of the heat. The CPU generates a substantial amount of heat which is then conducted to the copper cold-plate using microfins to maximize surface area and dissipation potential. Copper has the highest thermal conductivity of all the affordable metals available to us in the world of computing (about twice the thermal conductivity as aluminum at 25C - ~400W/mK), and so is almost always used in cold plates for CLCs.

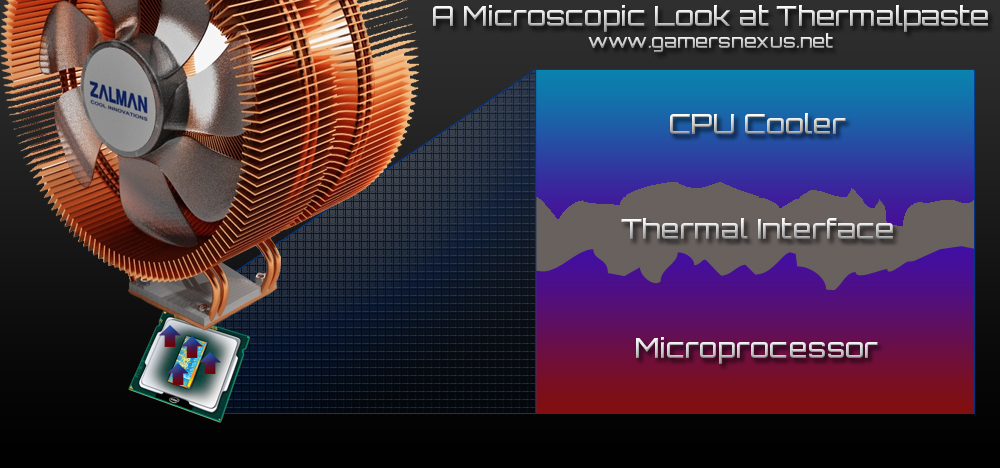

Thermalpaste sits as a thermal interface between the CPU's IHS (integrated heat spreader)—which is an imperfect surface—and the cold plate itself. The objective of thermal compound, as we discussed previously, is simply to serve as an intermediary thermal transfer medium between the imperfectly smooth surfaces of the IHS and cold plate. A total lack of thermal compound would mean air fills those pockets in the surface, which heats up and gets trapped between the CPU and cooler; thermal compound averages ~6W/mK or higher, making it an infinitely more effective thermal transfer interface than air, but still several factors of magnitude lesser than the copper surface. This is why too much thermal compound is a bad thing, but just enough creates an effective cooling source.

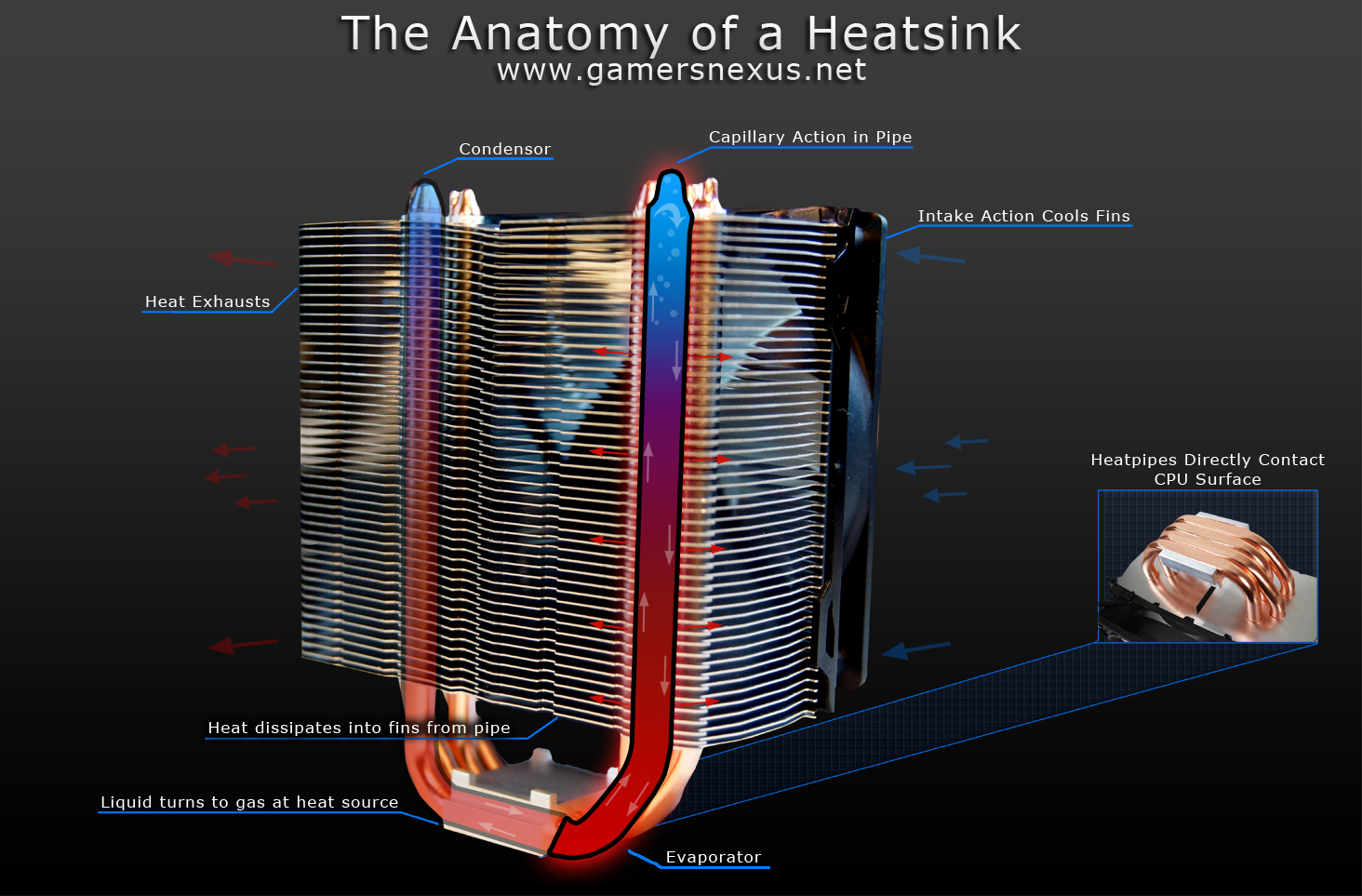

So heat goes from the silicon die (mounted on a substrate) to the IHS, into the copper interface, and is then conducted further upward. This is where the liquid comes into play: Using (usually) an electrically-safe coolant, the pump cycles liquid through the CPU cooling block and ducts heat away from the microfins; rather than using physical state phase changes, like in liquid-to-gas air cooling capillaries (below), the heat encounters cool liquid from the rad and is effectively whisked away, warming up the liquid for its return trip to the rad.

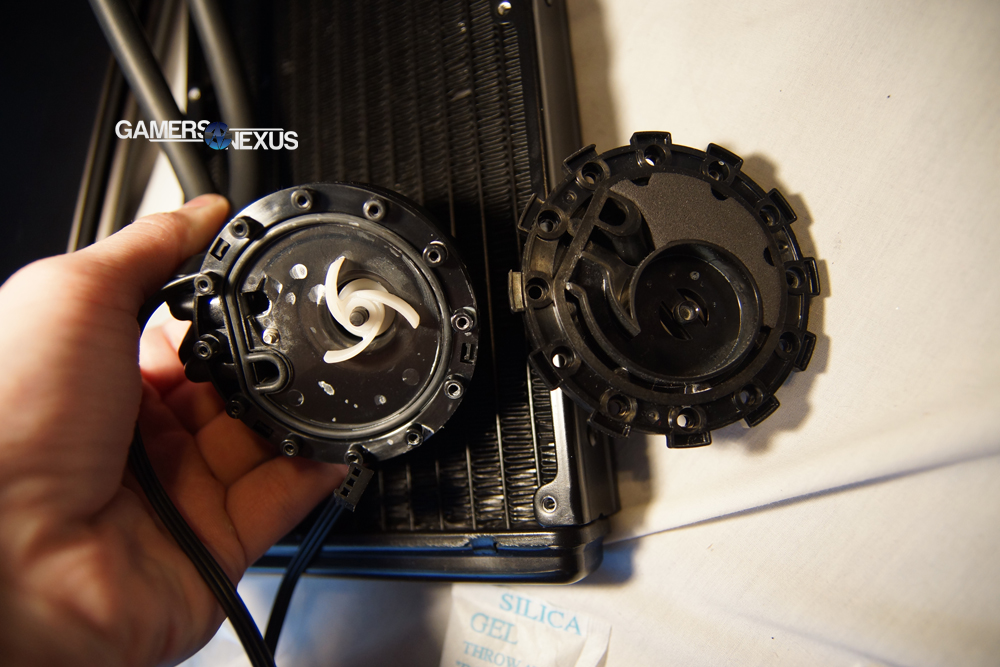

The liquid is pumped out of the block and into the intake tube via the CPU pump (at speeds measured in Liters-Per-Hour or pump RPM). Because I figured most of you wouldn't be keen to destroy your new CLC, I decided to take apart one of the Asetek-supplied models we tested -- here's what the actual pump looks like:

Click for massive image.

Click for massive image.

The little rotor spins at somewhere in the range of 2000-3000RPM for most Asetek-supplied pumps. The heated coolant eventually reaches the radiator from the insulated rubber hosing, at which point the liquid is directed down aluminum-walled piping within the radiator. Hundreds of aluminum fins line these pipes; basic laws of physics tell us that heat will do at least two things in this scenario: It'll try to achieve equilibrium across the thermally-conductive surface material (and thus will travel outward, sprawling across the aluminum fins, which are colder than the pipes), and it will move along a path of least resistance. As heat is conducted into the tiny fins, the air blown into the radiator from the fans will dissipate the heated air up-and-out of the case, maintaining a fin temperature that is conducive to the cooler's dissipation objectives.

Throughout the entire process described in the above paragraph, the coolant can be seen as 'shedding heat' and thereby being cooled by the dissipation and air intake processes; once it has completed its journey up-and-down the radiator, the now-cooled liquid reaches the return tube, where it is pulled back down toward the CPU block via the pump. The cool air reaches the block and the process begins anew.

The cooler the liquid is, the greater the potential for cooling the CPU.

What's in the Boxes?

All the boxes basically ship with the same items: You get your radiator, pump, tubing (all bundled in a pre-assembled package), mounting brackets, and fans all neatly packed away. The Corsair H90 and NZXT Kraken X40 both use identical (or almost identical, for purposes of performance) radiators and pumps, with the Kraken having hosing that is slightly longer and a customizable LED on the pump (as found on the i-series Corsair coolers). The same is true for the H110 and X60, which are just larger versions of their lower-number-identified brethren.

The only notable difference in contents shipped would be between the smaller (140mm) and larger (280mm) units, where obviously additional fans/screws are present. On the whole, everything you see above is what's included in all the boxes.

Continue to the next page for results and an interesting discussion on a supplier-driven hardware industry. (Sorry, we hate to paginate things, but the page would take forever to load otherwise).

The Boring Truth: Supplier-Driven Hardware

As with many other industries, much of the hardware industry is driven by independent suppliers who are contracted by the manufacturers we know and love. SSDs are a good example of this: Almost all of the NAND Flash on the market is supplied by Intel/Micron, Samsung, and Hynix; controllers are largely made by LSI (SandForce), Indilinx (now a subsidiary of OCZ), Samsung, and Intel. Manufacturers like Corsair and Kingstonpick-and-choose from suppliers, make custom firmware tweaks (among other things), and bundle it all as a product. This isn't to knock the way the industry or these particular companies operate - it's just an explanation as to how the interactions pan-out. You can read more about how SSDs are made in this article, if it interests you.

With this now noted, the supplier-manufacturer relationship also exists in nearly every other subdivision of the hardware market. Cooling is no exception.

Most CLCs on the market are engineered and supplied by a few powerhouse firms: Asetek - with the majority of the market, Swiftech, and CoolIT; Cooler Master has recently started manufacturing its own CLCs using in-house designs (a nice change), but has resultantly found itself at the end of Asetek's gun. That's what you get for manufacturing century-old technology, I guess.

The suppliers often operate with little input requirement from the customer, but certainly try to make efforts to differentiate products when possible. Asetek, for example, has a range of product offerings that can be selected by manufacturers, who can further customize their selection with LED-backlit nameplates (seen in NZXT's models herein), custom tubing lengths, fan design, and other minor alterations.

It's very build-a-bear-like in nature: Pick the model, pick accessories, put a sticker on it, ship it.

One noteworthy differentiating factor can be found in accompanying software, though: Software can be integrated with hardware to further drive same-supplier products apart, generally a responsibility of the manufacturer, and is demonstrated in NZXT's Kraken Control Panel and Corsair's i-Series software. The software typically gives users control over voltage modulation to the fans (speeds), LED lighting, and logging tools. All Corsair hardware suffixed with an 'i' demarcation is compatible (or will be compatible) with their control software, generally enabling fan speed control, thermal reporting (including liquid temperature), and other useful options for enthusiasts. The H90 and H110 are not compatible. Integration with PSUs is expected in the future.

Performance-wise? The coolers should all be theoretically very similar pre-software, which is what our below testing will aim to determine. The radiators are all pretty much identical at this point (in terms of surface area), the fans differ primarily in paint, and the pump is the same for all Asetek-supplied units. Asetek does iterate on its designs in generational jaunts, just like most other hardware, so modern-gen Asetek coolers should outperform otherwise-equivalent coolers of previous generations; all four coolers compared herein are on same-generation components. One instance of their technological advancements can be found in the form of their coldplate, which goes through minor performance-boosting revisions regularly (like tweaking the microfin design/spacing, currently on the 4th Gen coldplate).

Testing Methodology

We have a brand new test bench that we assembled for the 2013-2014 period! Having moved away from our trusty i7-930 and GTX 580, the new bench includes the below components:

| GN Test Bench 2013 | Name | Courtesy Of | Cost |

| Video Card | XFX Ghost 7850 | GamersNexus | ~$160 |

| CPU | Intel i5-3570k CPU | GamersNexus | ~$220 |

| Memory | 16GB Kingston HyperX Genesis 10th Anniv. @ 2400MHz | Kingston Tech. | ~$117 |

| Motherboard | MSI Z77A-GD65 OC Board | GamersNexus | ~$160 |

| Power Supply | NZXT HALE90 V2 | NZXT | Pending |

| SSD | Kingston 240GB HyperX 3K SSD | Kingston Tech. | ~$205 |

| Optical Drive | ASUS Optical Drive | GamersNexus | ~$20 |

| Case | NZXT Phantom 820 | NZXT | ~$250 |

| CPU Cooler | (This is what we're testing) | NZXT, Corsair | See above |

All of our testing is conducted in a temperature-controlled environment. Ambient is between 21C and 22C for CPU cooler tests. The graphs measure temperature in Delta over Ambient (C) - so the ambient temperature is subtracted from the component temperature.

Each test is initiated with a cold boot, where the system will sit idle for 15 minutes and collect thermal data. We use CPUID's HWMonitor Pro for thermal logging and tracking.

After this idle time, the system will launch a Prime95 instance running four torture threads on Large FFTs for maximum heat generation and power utilization. This is run for 15 minutes, throughout which the logging utility will collect the data we used in the below charts. A final round of idle time is allowed to ensure data consistency. Redundant tests are run in the event of unexpected results.

We keep a consistent case and airflow configuration for all CPU cooler tests.

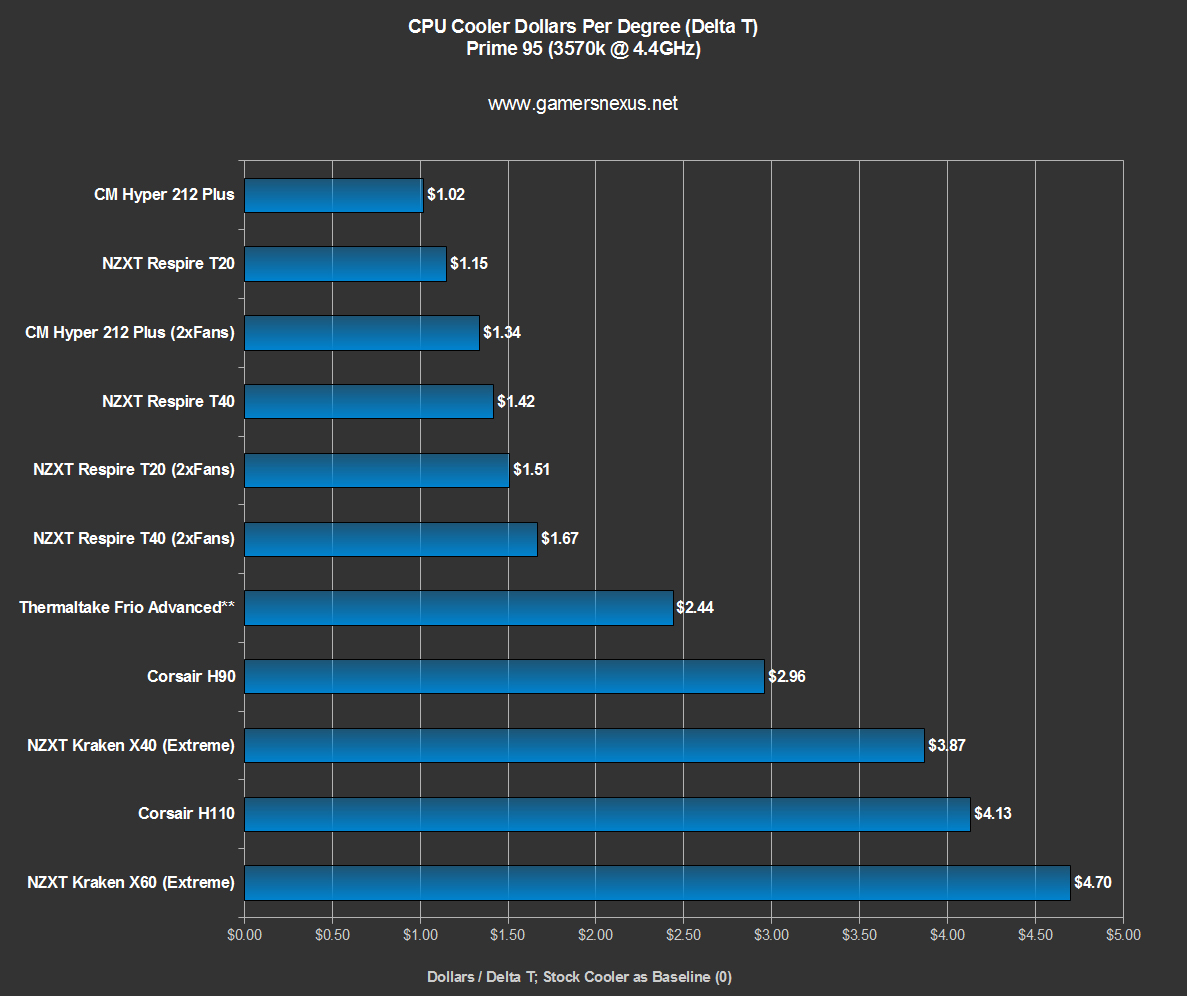

Our degree-per-dollar chart is measured by using the stock cooler as a temperature baseline. We calculate Delta T between the tested coolers and the stock Intel cooler, then divide price by Delta T (example: $65 / dT 28C = $1.85/degree C). This is used for buyers who are looking for a perspective on relative value and aren't necessarily after each individual degree. For value charts where coolers utilize two fans, we assume an average price of $8 per additional 120mm fan.

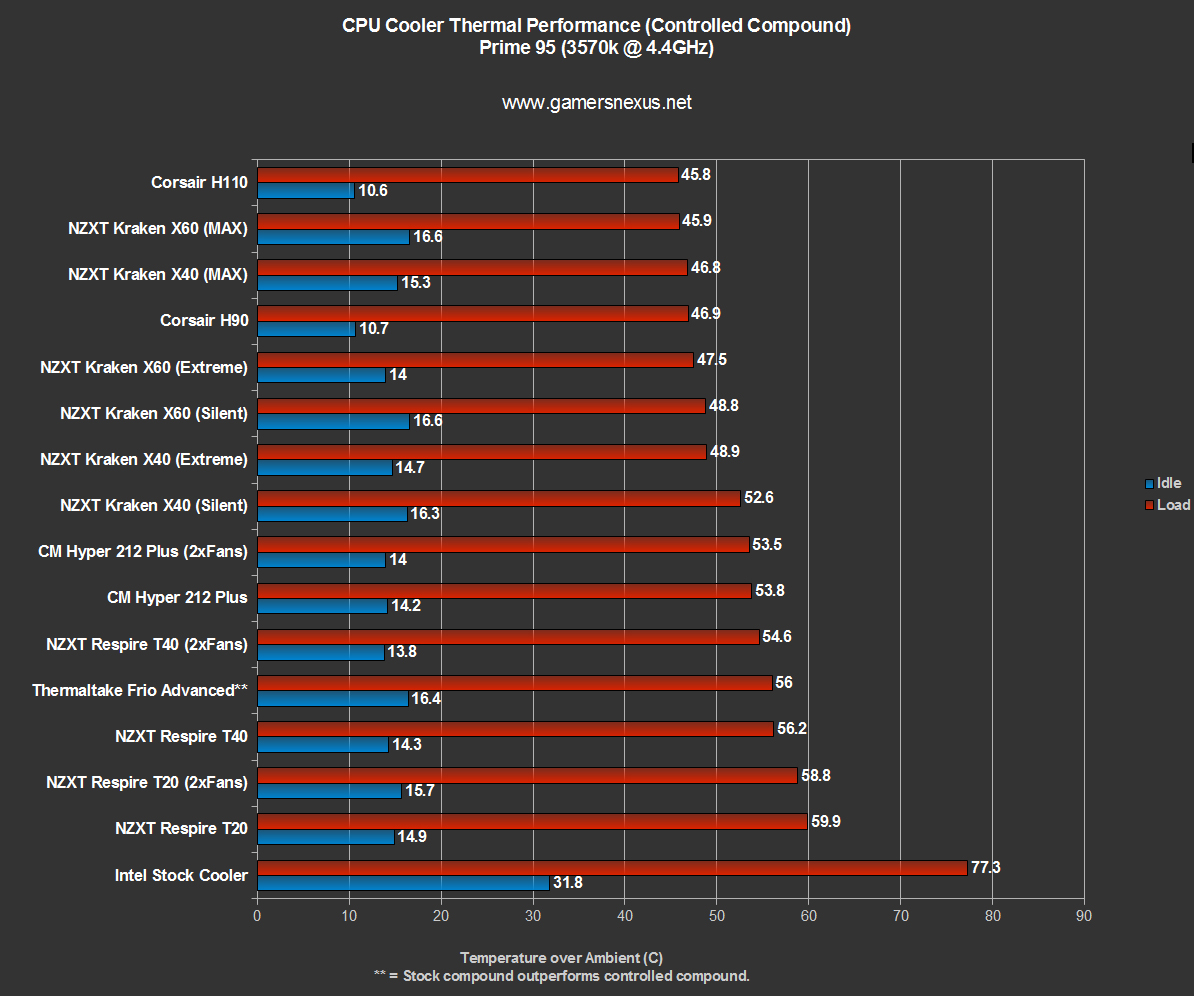

Corsair H110 & H90 vs. NZXT X60 & X40 Cooler Benchmarks / Review

For most cooler reviews, we run tests using both the stock thermal compound and our aftermarket / controlled compound (Antec Silver 6). The point of this is to determine how the cooler stands on its own by controlling the thermal interface, and as an added bonus, it helps determine if investing a few bucks in aftermarket paste would make up the difference between ranks.

For liquid coolers, at least ones with pre-applied paste, we've elected not to do this; the thermal compound used on stock CLCs tends to be already fairly good and is spread cleanly across the surface. We will continue using both stock and controlled compounds for air coolers.

As many of you have become used to, I like to highlight our predictions / thoughts prior to listing results in these reviews. My hope is that it gives you all a bit of insight as to how we look at coolers, and ideally equips you with a foundational analytical mindset when looking at cooler options -- especially those we haven't yet reviewed. In short, it's to equip you all for purchasing decisions and also give a bit of room for our own introspection.

In these tests, it was my prediction that the units would be nearly identical in cooling performance. The NZXT coolers ship with software, but these particular Corsair units do not -- for purposes of these tests, I hypothesized that when under identical load and at similar enough RPMs / pump RPMs, the coolers should be so close in performance so as to be insignificant. Going into testing, the biggest differentiating factor was simply going to be style and price. Let's see how these expectations held up on the bench:

A quick note on multi-fan configurations: We found on average a 2% decrease in temperature when an additional fan (push-pull) was added to the smaller units (X40/H90); the difference was 2%-5% on the larger units (X60/H110). We were not able to justify the purchases of extra fans on our bench, but your mileage may vary based upon CPU, intake/exhaust configuration, and enclosure.

And an additional note: We ran all tests with the units mounted in the top of the case for best comparison. Using our Phantom 820 test bed, I decided to additionally test the smaller units mounted in the rear (not shown in the above charts) just out of scientific curiosity -- turns out it was about 6C cooler than when mounted in the top. Working with Corsair and within our own team, we determined that it was more-or-less a matter of the way the case is designed; we did not see the same results when using different cases. The takeaway from this? It seems that, at least when using a Phantom 820 or 630 chassis, the smaller units mounted in the rear of the case perform with greater ability than the larger units in the top of the case.

The tests also saw use of all three of NZXT's primary settings: "Silent," "Extreme," and "Custom." Our custom profile just maxes out the RPMs, mostly out of curiosity. You shouldn't really 'count' the "(MAX)" tests in the above chart unless you fancy living inside a jet engine.

Rear-mounted 140mm radiators tend to perform significantly better in our case than when top-mounted.

Rear-mounted 140mm radiators tend to perform significantly better in our case than when top-mounted.

Strictly speaking to performance, the H110 wins out, hands-down. It outpaces NZXT's equivalent X60 at max settings (which are unbearably loud, as I'll discuss) and is slightly above the H90. Not much, though -- barely a degree. The Kraken coolers on 'Extreme' (somewhat tolerable noise levels) are close behind the H90's stock settings, and 'Silent' (which actually is barely audible - my preferred setting) trails just behind at 48.8C for the X60 and 52.6C for the X40. The overall delta across the range is only 6.8C, which is honestly not that massive of a difference when dealing with temps that are all sub-55C; it becomes much more noticeable if you're doing a more extreme OC than our system runs (4.4GHz 3570k @ 1.3V), but other than that, it'll come down to your own noise tolerance and bling requirements, if any.

Because the minimal difference means decisions will be hinged upon price and aesthetics, here's our regular dollar-per-degree chart (cost / delta T = dollars-per-degree, baseline established by stock cooler; additional fan costs are assumed at $8):

Overall, liquid is pretty expensive. It's effective and relatively quiet (when at non-insane settings), but expensive. Corsair seems to win-out once again in this chart, only this time it's purely in overall dollar-per-degree cooling value. If you need the absolute best cooling performance, well, it looks like the H110 is your bet (out of these units), but if you're after pure value and demand relatively-quiet liquid, the H90 is a very cost-effective option. It also is a more globally-compatible size - few cases support 280mm radiators right now.

The Big Class: Kraken X60 vs. Corsair H110

NZXT's Kraken X60 is tough to justify. It's around $140 on most retailers right now, and at that price, you're at an awkward mid-point between a custom loop and a traditional CLC. Corsair's H110 isn't much better at $130, but making the choice between the two is difficult: For pure, objectively-superior, raw performance, the H110 stands as the victor. Corsair's 280mm H110 runs about 2C cooler than the 'Extreme' setting on the X60, though if you can tolerate gaming next to a vacuum cleaner, the maxed X60 is about identical in performance (within scientific margin of error) and includes an LED. Neat.

When we account for more subjective preferences and down-class objective thermal performance, two key variables are introduced: Noise and appearance. This is where the Kraken units (both of them) pull ahead -- you suddenly have the potential to configure a custom fan-speed curve, optimize for a low noise threshold that utilizes bursty fan-speeds for rapid dissipation, and generally maintain a quieter system overall. Temperature might be a few degrees warmer, but for many people, gaining 3C in favor of quieter cooling could be worthwhile. Looks? Well, you can customize the color of the NZXT. logo (period included) and how it pulses, or doesn't, so I suppose that's cool.

Personally? Between the two larger coolers, I'd choose the X60 -- but only for its ability to customize the fan-curve (something only possible on i-series Corsair coolers). One interesting note is that the X60 has a very high idle temperature when compared against the H110 - so take that into consideration if you're trying to maintain a cooler room temperature.

The H110 is the clear winner for pure performance, though.

Let's look at the smaller options.

The Little Class: Kraken X40 vs. Corsair H90

The under-load difference between the X40 on 'silent' and the H90 is more noticeable than the 3C differential between the Silent X60 and H110, totaling at around ~6C favoring the H90. As for idle, that's about as oddly-high on the X40 as it is with the X60, even when on 'Extreme' and 'Max' (custom) settings, though the H90 runs beautifully at 10.7C idle.

As discussed above, the H90 has the absolute best overall value, runs quietly enough (in the 30-35dBA range), and cools exceptionally well. To the same tune as the X60 vs. H110, the Kraken unit does have the LED and software control panel, which is probably worth something to the right people (you can decide if that includes you), but my choice for the smaller units would be Corsair's H90.

That pretty much covers it all: Between only these units, my choices would be the H90 (for the small option) or X60 for the larger option. Looking at the chart, it's apparent that some air coolers are close in performance and significantly cheaper, so you may even consider the air route if liquid isn't a hard requirement. Don't forget: It is possible to buy/upgrade an air cooler that's quiet.

Let us know if you have any questions about all of this!

- Steve "Lelldorianx" Burke.